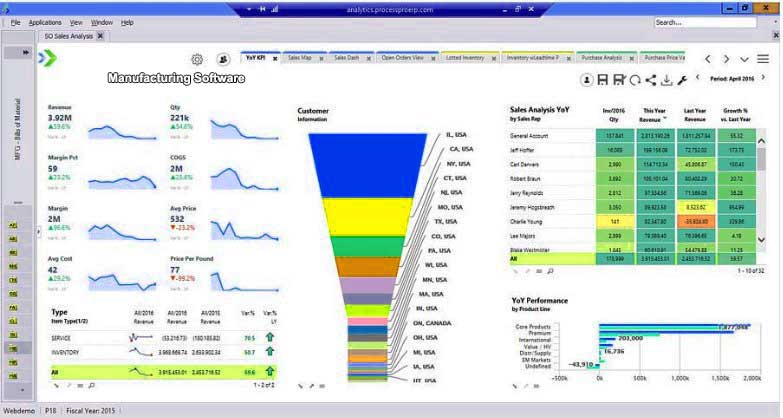

Manufacturing Software

Manufacturing software is a suite of tools that helps manufacturers manage their core business processes, including production planning, inventory management, quality control, and customer relationship management (CRM). By automating and streamlining these processes, manufacturing software can help manufacturers improve their efficiency, reduce costs, and increase profitability.

Types of Manufacturing Software

There are a variety of different types of manufacturing software available, each designed to meet the specific needs of different manufacturers. Some of the most common types of manufacturing software include:

- Enterprise resource planning (ERP) software: ERP software is a comprehensive suite of tools that integrates all of a manufacturer’s core business processes into a single system. ERP software can help manufacturers manage everything from production planning to accounting to customer service.

- Manufacturing execution systems (MES) software: MES software is a type of software that focuses specifically on the production process. MES software can help manufacturers track and manage production schedules, inventory levels, and quality control.

- Computer-aided design (CAD) software: CAD software is used to create and edit engineering drawings and 3D models. CAD software is widely used in manufacturing to design products and create prototypes.

- Computer-aided manufacturing (CAM) software: CAM software is used to convert CAD drawings into G-code, which is the programming language used to control CNC machines. CAM software is used in manufacturing to produce products from raw materials.

Benefits of Using Manufacturing Software

There are many benefits to using manufacturing software, including:

- Improved efficiency: Manufacturing software can help manufacturers to automate and streamline their core business processes, which can lead to significant time and cost savings.

- Increased visibility: Manufacturing software can provide manufacturers with a real-time view of their operations, which can help them to identify and address problems quickly and efficiently.

- Improved quality control: Manufacturing software can help manufacturers to improve their quality control processes by tracking and managing product defects and non-conformances.

- Reduced costs: Manufacturing software can help manufacturers to reduce costs by automating tasks, streamlining processes, and optimizing inventory levels.

- Increased profitability: By improving efficiency, visibility, quality control, and reducing costs, manufacturing software can help manufacturers to increase their profitability.

How to Choose the Right Manufacturing Software

When choosing manufacturing software, it is important to consider the following factors:

- Size of business: Manufacturing software is available for businesses of all sizes, from small businesses to large enterprises. Choose a solution that is scalable to meet the needs of your business as it grows.

- Industry: Some manufacturing software solutions are designed for specific industries. Choose a solution that is tailored to the needs of your industry.

- Budget: Manufacturing software can range in price from a few thousand dollars to hundreds of thousands of dollars. Choose a solution that fits your budget.

- Features: Manufacturing software solutions offer a variety of features. Choose a solution that has the features that you need.

- Ease of use: Manufacturing software solutions can vary in terms of ease of use. Choose a solution that is easy to use and train your employees on.

Conclusion

Manufacturing software is an essential tool for manufacturers of all sizes. By choosing the right manufacturing software solution and implementing it effectively, manufacturers can improve their efficiency, visibility, quality control, reduce costs, and increase profitability.

Here are some examples of how manufacturing software can be used in different industries:

- Automotive: Automotive manufacturers use manufacturing software to automate and streamline their production processes, manage their inventory levels, and ensure the quality of their products.

- Aerospace: Aerospace manufacturers use manufacturing software to design, produce, and test complex aircraft and spacecraft components.

- Electronics: Electronics manufacturers use manufacturing software to produce electronic devices, such as smartphones, computers, and televisions.

- Food and beverage: Food and beverage manufacturers use manufacturing software to produce safe and high-quality food and beverage products.

- Pharmaceutical: Pharmaceutical manufacturers use manufacturing software to produce safe and effective pharmaceutical products.

If you are a manufacturer, consider investing in manufacturing software to improve your operations and increase your profitability.